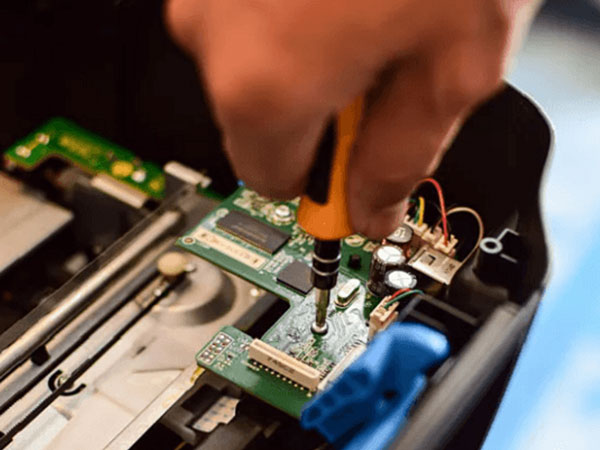

Finished Product Assembly

PCBA finished product assembly is the complete assembly of customer finished products. Assembly not only includes the production of printed circuit boards (PCBs), but also involves the soldering and processing of surface mount/plug-in components to electro-mechanical components, such as the manufacturing of plastic and hardware casings, the installation and wiring of cables or harnesses, and the installation of sub-components.

What is required for PCBA finished product assembly?

The information we need for product

assembly is as follows:

- BOM list;

- Schematic diagram;

- Assembly drawings;

- Wiring connect list;

- Test guidance/instructions;

- Sample (if has).

Types of PCBA Finished Product Assembly

1. Assembly of finished plastic shell

products

Lonstar has rich experience in the assembly

of multi-purpose plastic products, mainly involved in industries such as

automotive electronics, measuring instruments, controllers, communication

device, network equipment, data recorders, medical equipment, etc.

2. Assembly of finished hardware shell

products

Our diverse metal box assembly capabilities

enable us to provide our customers with various standard configured products or

fully customized according to your exact specifications.

3. Wire assembly

We provide a variety of wire finished product assemblies, offering high reliability wire assemblies including discrete wires, molding, sealing, and high-power cable parts.

QUICK LINK

SHIPPING METHODS

CONTACT US

LEAVE A MESSAGE

Link