PCB Assembly

Lonstar provides high quality PCB Assembly service, from PCB manufacturing, components sourcing to assembly, also offers customized package, on time delivery and fast response always.

PCBA manufacturing process:

SMT → DIP plug-in processing → PCBA testing → Finished product assembly

1

SMT: solder paste stirring→solder paste printing→SPI→SMD mounting→reflow soldering→AOI→rework.

Through SMT , components are mounted on the circuit board, and online AOI automatic optical inspection is performed if necessary. After inspection, set the perfect reflow oven temperature data and the board will go through reflow. After the necessary IPQC inspection, the plug-in material can be passed through the circuit board using the DIP plug-in process, and then flow through the wave soldering for soldering. After the above processes are completed, QA is also required to conduct a comprehensive inspection to ensure product quality.

DIP process: plug in → wave soldering → foot cutting → hand soldering processing → board washing → quality inspection.

PCBA testing: PCBA test can be divided into ICT test, FCT test, aging test, vibration test, testing in hard environment etc.

PCBA testing is the most critical quality control step to ensure the PCBA working 100%. It is necessary to strictly follow the PCBA test standards and test the points of the circuit board according to the customer's test plan.

Finished product assembly: Assemble the PCBA with enclosure, then test it, and finally it can be shipped.

2

3

4

Stencil

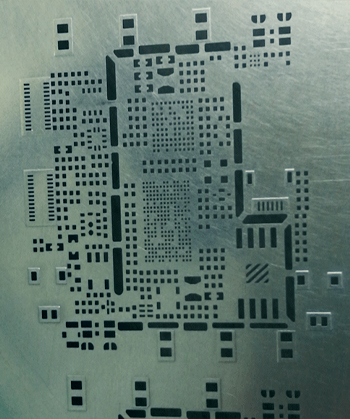

Volume PCBA

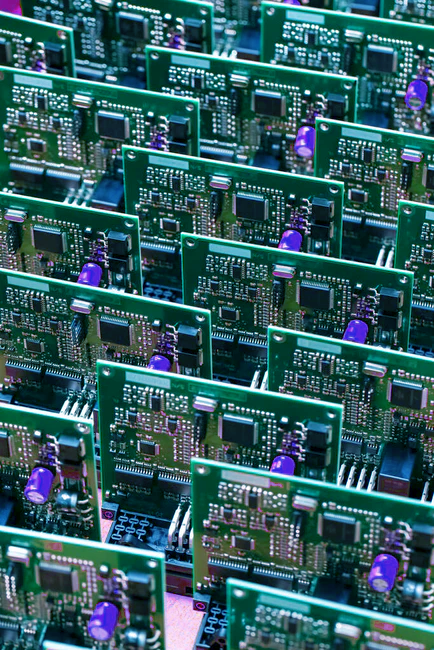

Prototaty PCBA

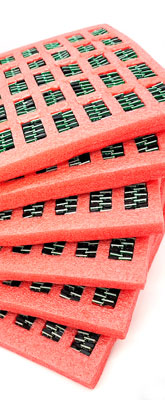

PCBA Package

Lonstar provides different types of customized package according to our clients' products.

The packaging style is as follows:

Vacuum Package → Static Bag→ Cotton Card Slot→Carton Board Slot→ Carton Board Slot with Bubble→Custom Plastic Plate→Custom Logo Print Carton

QUICK LINK

SHIPPING METHODS

CONTACT US

LEAVE A MESSAGE

Link